|

|

#121

|

||||

|

||||

|

Quote:

Quote:

I am sorry Viper but it does not change the fact you cannot precisely meter the fuel thru an intake, either. Quote:

Quote:

|

|

#122

|

|||

|

|||

|

Quote:

Because you're injecting fuel under pressure, you can positively atomise it, achieving a considerably lower Sauter mean diameter of fuel droplets than is possible with a simple carburettor, which means that it will evaporate much faster. This means that more of the temperature drop happens earlier in the compression process, which increases the overall efficiency bonus. Once the fuel has evaporated, the mixture distribution problem goes away. Quote:

Quote:

Fuel distribution may be a problem at low manifold temperatures where the fuel fails to evaporate fully, but that is a separate problem. You seem to be mostly hung up on fuel metering issues, which certainly exist for naturally aspirated engines with carburettors, especially away from their design point. However, fuel metering is not especially important at high power if you don't care about emissions. You run rich of stoichiometric, and fuel flows say +/- 5% won't make a great deal of difference to power output. Obviously the SFC is pretty bad at that point; you can clearly see this on the SFC curve in Lovesey's paper. Mixture distribution is not a problem at high induction manifold temperature. The reductions in supercharger work and intercooler size are far more important than the slight increase in fuel mass fraction which you might suffer from the need to keep the leanest cylinder sufficiently rich to avoid detonation. The cost of a single point system is far lower than a multi-point system, and the fuel pressure required is lower than for true direct injection. (Port injection is a pretty horrid compromise which only makes sense if the alternative is a carburettor which would produce bad mixture distribution.) For a supercharged spark-ignition aero-engine, operating at a fixed non-dimensional power setting, provided that you've got enough induction manifold temperature to avoid condensation, the mixture distribution will be good and the single point system wins. Multi-point FI is an expensive solution to mixture distribution problems. It is great for naturally aspirated engines, and probably pragmatic for turbo-normalised engines, especially if the engine manufacturer isn't responsible for the turbocharger. But if you're using a mechanical supercharger and will mostly operate the with reasonably high induction manifold temperatures, then there's no great mixture distribution problem unless your induction manifold is horrible, so multi-point injection offers limited benefit, whilst single point injection into the eye of the supercharger reduces supercharger drive power requirements. So single point injection is a pretty obvious choice. Now, if you're designing a sports car engine, you might supercharge it to get high power, but most of the time it would operate at very low non dimensional power settings, so mixture distribution would be a major problem with single point injection, and therefore you'd probably go for multi-point FI. But that's because the sports car engine isn't really designed for high performance. It's designed to make an expensive noise and very occasionally provide bursts of acceleration to impress the girl in the passenger seat. Most of the time it's practically ticking over, and so you're much more bothered about part-load characteristics than would be the case for an aero-engine. You're also trying to meet modern emissions regulations, which means that you're paranoid about stoichiometry so that you don't poison your catalyst. It's a totally different world, with different trades and different drivers. |

|

#123

|

|||

|

|||

|

Quote:

|

|

#124

|

||||

|

||||

|

http://www.slideshare.net/rjperforma...rj-performance

It works in any engine to increase power and performance over any other fuel metering system no matter if the intake is supercharged or not. http://www.steerbythrottle.com/hccyong/files/DFI.pdf Quote:

A good primer article on Direct Injection. It explains very well the difference between the various types of fuel injection and why Direct Injection is the ultimate fuel metering system for power and performance. http://www.driverside.com/auto-libra..._injection-350 Here is a good article that explains the German Direct injection systems in easily understandable terms: http://www.motorcycleproject.com/mot...xt/inject.html The German systems were far from perfect but they certainly did their job and allowed them to level the playing field in terms of aircraft engine performance. IIRC, the British and United States did a combined effort to develop a Direct Injection engine that was used in a tank at the end of the war. |

|

#125

|

||||

|

||||

|

Quote:

Viper, direct injection is a fuel metering system. Supercharging is an intake system and does not have a thing to do with fuel metering. It is two completely separate things you want to combine. You point to the thermal benefits of introducing the fuel ahead of the supercharger instead of downstream of it. I agree it is there when compared to introducing fuel downstream of the supercharger in your INTAKE SYSTEM. Got it but that does not make it more thermally more efficient that directly injecting the fuel in the combustion chamber. You are not looking at the heat capacity but are stuck on upstream vs downstream fuel introduction for your intake. As Rolls Royce points out, direct injection is much more efficient than metering your fuel downstream or anywhere in the intake system. Just because that small part of the intake system becomes more efficient vs introducing fuel downstream does not make the whole system more efficient. A simple illustration of that basic principle. 1006 J/kgC – Specific Heat Capacity of Normal Air 460 J/kgC – Specific Heat Capacity of Steel 2100 J/kgC – Specific Heat Capacity of Gasoline To change the temperature of a mass of 1 Kg of each by 2 degrees…. Air = 1006 J/kgC * 1kg* 2 C = 2012J Fuel = 2100J/kgC*1kg*2 C = 4200J Steel = 460J/kgC * 1kg * 2 C = 920J Our 4200J of fuel energy goes to cool the 15C air… 4200J * 1kg /1006J/kgC = Change in T = 4.17 C 15C - 4.17C = 10.83C Why do you think direct injection is the ultimate fuel metering technology and so desirable to have in an engine? If was not for the complexity and expense, all engines would be direct injected because it is the most efficient system mankind knows of at the present for metering fuel. Rolls Royce also shows in the article you posted their system is not as efficient as directly injecting fuel into the combustion chamber combined with your supercharged intake. Why? YOU STILL MUST HAVE A FUEL METERING SYSTEM ON YOUR ENGINE. Introducing the fuel ahead of the supercharger does not eliminate the basic problem of NON DIRECT INJECTED FUEL METERING SYSTEM, uneven fuel mixtures found by introducing fuel ANYWHERE in the intake system. The only way to eliminate that is too directly inject fuel into the combustion chamber. Direct injection engines with a supercharger STILL benefit from that supercharger intake system. Last edited by Crumpp; 06-24-2011 at 03:45 PM. |

|

#126

|

||||

|

||||

|

Quote:

The drawbacks to direct injection are the expense and complexity. The BMW801 series used 14 high pressure fuel pumps and consisted of more parts than the entire rest of the engine. The supercharger technology of the allies combined with better fuels restored the balance. You cannot point to Direct Injection technology and say it was decisive and gave the German engines better performance over the allied ones anymore than you can point to better fuel quality and supercharger technology of the allies as being better than the German engines. In the air war over Europe, all sides developed their engines and fielded 2000 hp plus designs by the wars end. The implications made a few folks that fuel technology was decisive are not correct when one takes in the whole picture. Fuel quality and supercharger technology simply maintained the balance with fuel metering technology as well as superior chemical engineering. That any of these engines were routinely operated outside of their published guidelines is another ludicrous idea hatched in the gaming world but that is another subject. Last edited by Crumpp; 06-24-2011 at 04:27 PM. |

|

#127

|

|||

|

|||

|

Quote:

If the fuel has evaporated, and is in a gaseous phase, which is perfectly reasonable if the induction manifold temperature is high, the exact same argument applies; inertial separation of species within the gaseous mixture is unlikely because the forces are insufficient to overcome the diffusive tendency of the gas. Quote:

The benefit of single point injection into the eye of the supercharger is that it improves the effective isentropic efficiency of the supercharger, and thus reduces supercharger work, increasing the brake horsepower output of the engine when compared with multi-point injection into the cylinders or ports. I'm getting pretty tired of trying to explain this relatively simple concept. Here's a nice big paper. It's got a lot of interesting stuff in it, but the bit that is germane to this discussion is the analysis of the effects of water injection upon compressor performance. It doesn't matter whether you're injecting fuel or water, the latent heat reduces the temperature rise through the compressor, which is analogous to an increase in compressor efficiency. Happy reading. |

|

#128

|

||||

|

||||

|

In one of Viper's earlier points he argues that if you don't care about emissions and purposely run a bit rich, then minor variations in fuel/air ratio will not cause problems. Temperatures on the downstream side of the supercharger ought to be plenty high enough to cause evaporation of the fuel droplets, particularly if you aren't intercooling.

On a turbocharged, intercooled engine I'd wager that direct injection would be superior since the turbo is already much more thermodynamically efficient than a supercharger. But on a supercharged engine where the supercharger can pull as much as 30% of the crankshaft's power it's a sound engineering decision to try to increase that efficiency foremost. |

|

#129

|

|||

|

|||

|

Quote:

"The proposed changes to units equipped with Bf 109 were as follows: OKL, Lw.-Führüngstab, Nr. 937/45 gKdos.(op) 20.03.45" (it is not an original document either) unit - on hand - serviceable - type "I./JG 27 - 29 - 13 - Bf 109 K III./JG 27 - 19 - 15 - Bf 109 K and some 109 Gs III./JG 53 - 40 - 24 - Bf 109 K and some 109 Gs IV./JG 53 - 54 - 27 - Bf 109 K and some 109 Gs" for the use of 1.98ata boost on 109K-4s. Just have to love that double standard. |

|

#130

|

|||

|

|||

|

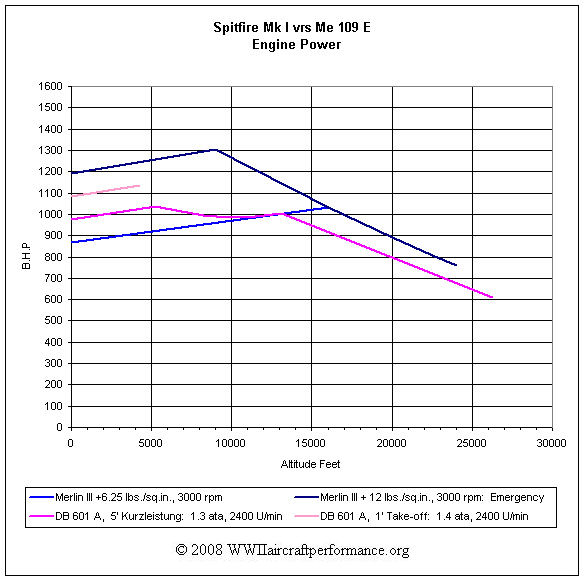

The proof is in the pudding. The Merlin III/12lb boost was producing much more power than equivalent DB601 engines:

From what I can gather on the web, the DB601 also had a 100 hr TBO versus 240 for the Merlin. Does anyone have other figures? |

|

|

|